Wastewater Treatment Plant with UASB ANAEROBIC DIGESTER to remove high COD & renewable energy sources.

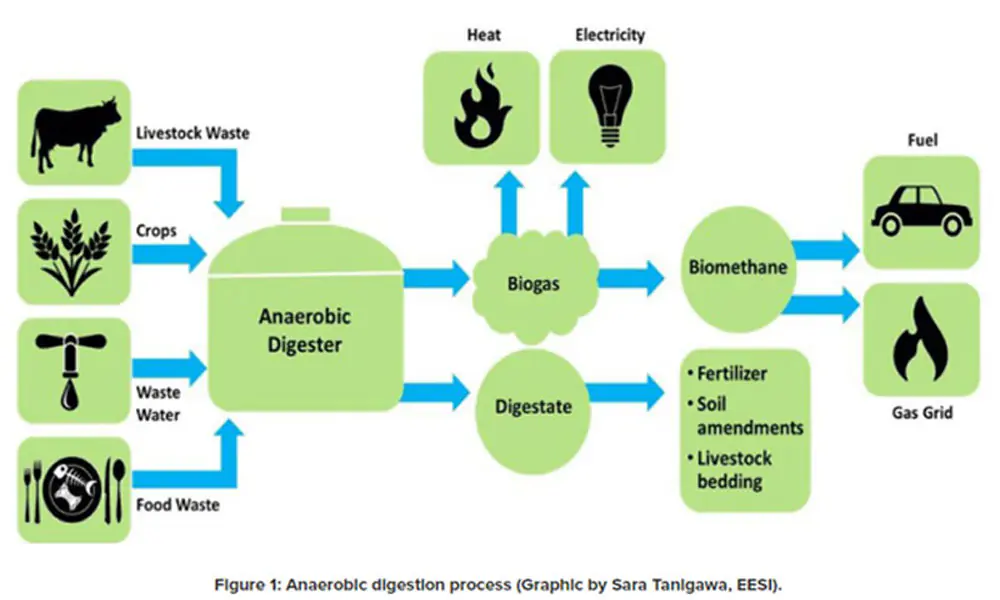

Organic waste (both solid waste and wastewater) from the palm oil industry, tapioca industry, and so on, has the potential to be processed into biogas which is a renewable energy source.

Microorganisms in the Anaerobic Digester decompose organic materials in waste into biogas through a series of stages including hydrolysis, acidogenesis, acetogenesis, and methanogenesis, with the biogas produced consisting of methane gas CH4, carbon dioxide CO2, and other gases such as H2S and ammonia.

HydromasterAD is an anaerobic digester system developed using UASB technology. It optimally reduces COD levels by implementing an excellent biomass separation system, resulting in highly effective mixing of granular biomass, liquid waste, and biogas. Several types of HydromasterAD have been developed to suit the characteristics of wastewater in each industry, ranging from 2,000 mg/L to 80,000 mg/L of COD.

In contrast to aerobic systems with aeration which produce a lot of sludge as the end result of activated sludge, this system runs without aeration so that this anaerobic system is very low in energy and efficient and actually produces energy.

Usually, to achieve wastewater quality standards that meet environmental quality standards, an aeration process is required after this anaerobic process.

Advantages of the HydromasterAD system

- The reduction in COD levels reached 85% to 95%

- Producing biogas as a renewable energy source

- Durable tank with special anti-corrosion coating for use > 30 years.

- Efficient with a high Organic Loading Rate, saving land compared to other systems.