In 1991, AMCON introduced the VOLUTE™, commonly known as the multi-disk screw press, to a world where no one had ever seen such a unique filter element before. AMCON's experience since 1974 as an operator of sludge dewatering and wastewater treatment plant equipment led them to develop an easy-to-use machine.

Amcon's Volute™ technology as a pioneer and market leader has been installed and operating more than 30 units in Indonesia since 2008 to handle various types of industrial waste and more than 5000 units in more than 77 countries in the world.

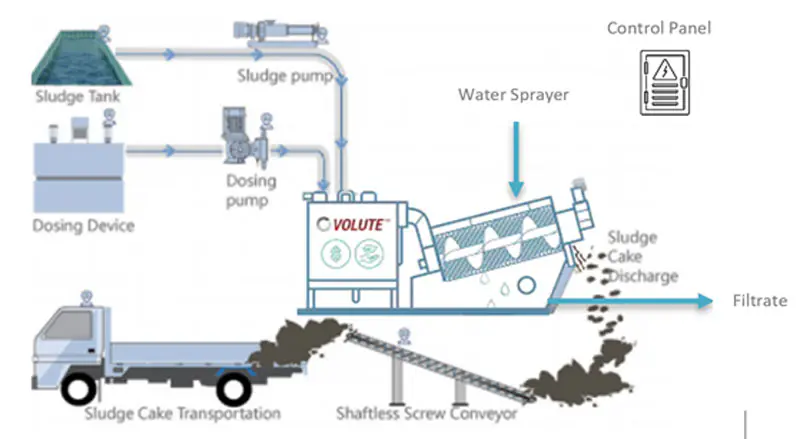

The dewatering system is applied primarily to sludge from anaerobic and aerobic biological systems as well as sludge from DAF systems or a combination of both with Total Solids of 0.1% – 8% ppm which require special handling.

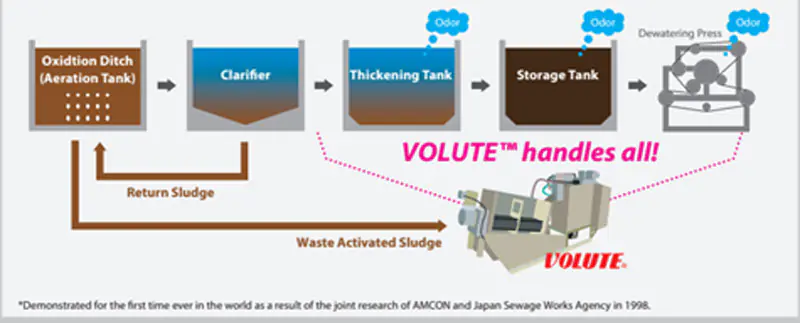

Before Volute™ technology was invented, sludge usually needed to go through a pre-thickening process before being dewatered separately.

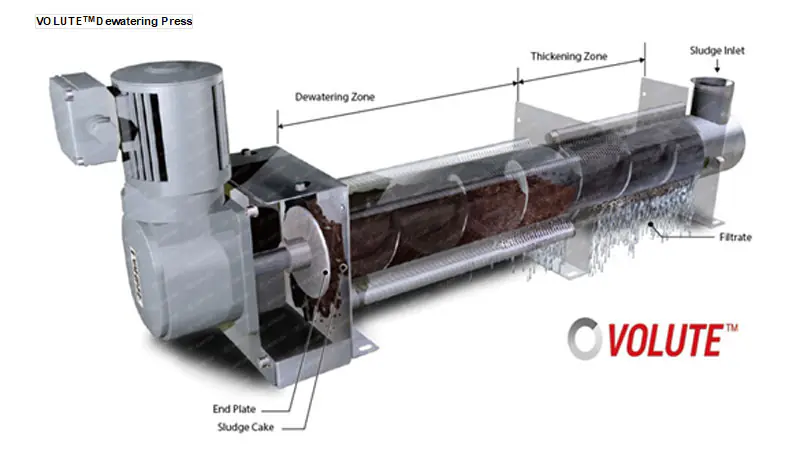

With the invention of Amcon's Volute™, both processes can be carried out simultaneously in a filter element consisting of two types of rings, namely a fixed ring and a moving ring, and a screw that pushes the filter element and moves, while compressing the sludge. The cavity between the rings and the screw pitch is designed to gradually narrow towards the sludge cake outlet and the pressure of the filter element increases due to the volume compression effect, which compacts and removes water from the sludge.

Advantages of the Amcon dewatering system:

- Easy operation and maintenance and can operate 24/7 without an operator.

- Compact and efficient design so it saves space, water and electricity.

- There are no problems in terms of noise and vibration because there are no components rotating at high speeds.

- Its self-cleaning mechanism allows for handling sludge with high oil content.

- Significantly reduces odor when drained directly from aerobic sludge

- The resulting sludge cake can contain > 20% Dry Solids.

- Can be applied to municipal, industrial, plantation, mining, and other wastewater